At MCR, we actively promote the development of our customers’ expertise to independently navigate common challenges.

However, in instances where issues become more intricate, requiring external assistance, our comprehensive troubleshooting services for operations come into play:

These services are meticulously designed to deliver prompt and effective solutions, ensuring the uninterrupted functionality of your systems. While autonomy is encouraged, our dedicated support is readily available for specialized intervention when challenges demand it. For more information, please contact us.

In critical situations where the wastewater treatment process is at risk of rapid deterioration, potentially exceeding environmental regulations and prompting production reductions or halts, our on-site emergency assistance is crucial. Our experienced team has been called upon numerous times to swiftly respond to emergencies, aiding operating teams in regaining control.

Upon receiving an emergency call, we initiate an accelerated problem-solving process. This involves defining the issue, assessing short-term risks for the company, and establishing a focused action plan to promptly mitigate these risks.

For more information about our rapid on-site emergency assistance service, please don’t hesitate to contact us.

With a specialty dating back to 1995, MCR has been at the forefront of addressing operating problems in the realm of wastewater treatment. Our extensive experience has allowed us to develop unique expertise in resolving complex challenges. Over the years, we have honed our skills and crafted tools to diagnose and find solutions to various issues, including:

In addition to these specialized problem-solving capabilities, we offer expertise to support our customers in their operations, including:

Our audit services are tailored to cater to different needs, with three types of audits available:

For further information or to discuss your specific requirements, please do not hesitate to contact us.

Our Quick Audit service is designed for swift and targeted intervention. Typically conducted by a single expert over two days at your site, this audit is specifically focused on addressing a particular problem that your company has been experiencing.

The primary objective is to rapidly identify potential causes, whether related to operations, equipment, or monitoring programs and laboratory testing. Following this thorough assessment, an action plan is formulated. Depending on the findings, this plan may lead to additional activities aimed at resolving the identified issues.

For more details about our Quick Audit service or to discuss how we can assist your company, please feel free to contact us.

Our Process Audit service is tailored for clients seeking to augment their process capacity or those facing recurring environmental exceedances or risks. The primary objective is a comprehensive review of operations and treatment performance, leading to the development of an action plan for equipment upgrades or operational improvements.

Key features of our Process Audit:

For more information on our Process Audit service or to discuss your specific requirements, please contact us.

Our Treatment Plant General Audit is a comprehensive service designed for customers seeking an in-depth operational risk assessment of their wastewater treatment facilities. This traditional audit focuses on equipment, works, and operational documentation available from the company. No testing with our diagnostic equipment is included in this type of mandate.

Key Features of the Treatment Plant General Audit:

For more detailed information about our Treatment Plant General Audit service or to discuss your specific requirements, please feel free to contact us.

Introduction:

The introduction of new chemicals or changes in the dosage of existing products in your production can pose potential risks to biological treatment processes. Bacteria, whether aerobic or anaerobic, may be susceptible to the toxic or inhibitory effects of certain chemicals, leading to a significant loss of activity and potential malfunction of the biological treatment process.

Our solution:

To mitigate this risk, we offer advanced toxicity testing for activated sludge bacteria. This testing utilizes respirometry, following OECD and ASTM guidelines. The results are presented in a format that allows easy translation into the actual quantity of products used in real-world scenarios.

Key benefits:

Decision-Making Support:

Armed with this data, you can make informed decisions about the potential risks of using specific products in your treatment process. Over thirty customers have already utilized our services, testing more than 200 products before integrating them into their production.

For more information about this service or to request an example of a respirometric toxicity report, please contact us.

Introduction:

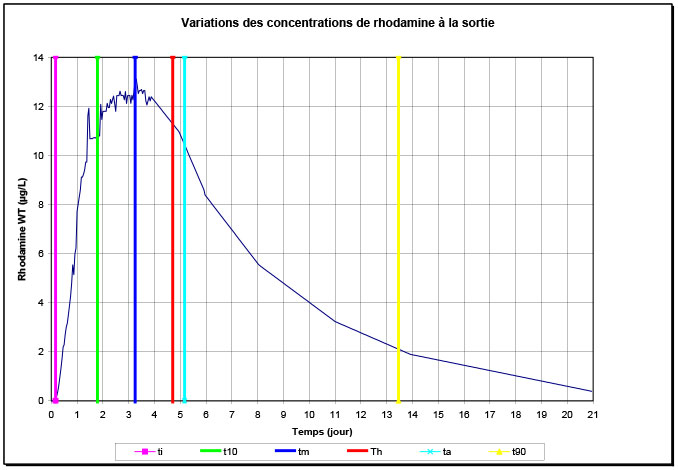

Our tracer study using rhodamine WT has proven to be a valuable tool in wastewater treatment, with practical applications since 1995. MCR has conducted numerous evaluation projects focused on lagoon short-circuiting and flow measurements.

Methodology:

To conduct these services, we utilize the Trilogy fluorometer from Turner along with the necessary equipment to inject and meter rhodamine, sampling it at various points within the lagoon.

Key Applications:

Analysis and Recommendations:

Benefits:

Optimizing lagoon efficiency can lead to significant cost savings compared to expanding wastewater treatment plants.

For more information about our tracer study service or to request an example of a tracer study report, please contact us.